Tag: maintenance

-

Replacing the head sanitary hose – part 3

Sunday dawned. The forecast said there would be rain in the afternoon, and the tide wouldn’t be right until about lunch time to be alongside for power (to do a different job where we needed to run the multi-tool). Today was to be the day we made sure the seacock would close fully, the old…

-

Replacing the head sanitary hose – part 2

With the efforts of Friday, we had got the head out, and the top panel and “pillar” portion of the steel holding tank surround. Onwards to getting the rest of it out! Along the way, we did some GPS wiring while thinking about how to take things to pieces – we wanted to be alongside…

-

Replacing the head sanitary hose – part 1

Blue Opal’s head has had a bit of a pong since I got her, even with lots and lots of water flushed through (and Jabsco “Toilet Fresh Clean”.. actually, I think that smelled worse than the head itself; sickly sweet). The manual Whale V pump has also been annoying me, because it was installed about…

-

RIP GPS mushroom

The GPS on Blue Opal has been failing recently, claiming that it can’t get a fix. The common answer in the forums is that the battery has died, and should be replaced – spot welding the tabs will be the hard bit, but doable. So, I took mine off the railing, and discovered that it…

-

Running a new bilge pump pipe

The existing pipe for Blue Opal’s electric bilge pump is some sanitation hose that looks like it might have been installed when the boat was built. I’ve been getting odd bits of water in the bilge that can’t be explained by leaks in the stern or at the mast, so I decided to clean and…

-

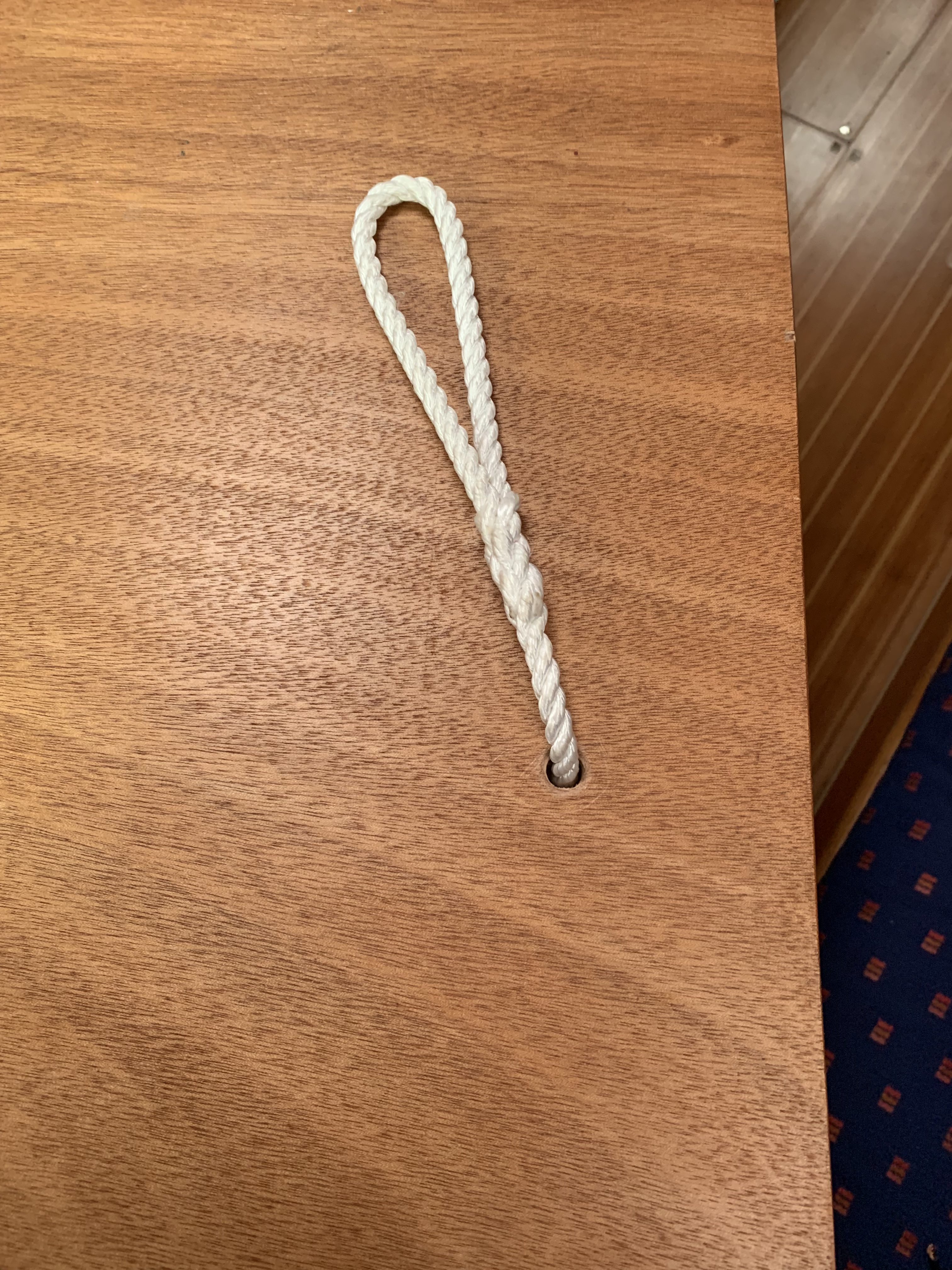

Pull-handle for the water tank locker

Blue Opal’s water tanks are in the bow, under the master cabin berths. The boards that cover the lockers are a pain to remove, because they’re a friction fit. However, given there are two shut-off valves in the locker, I decided to make it a bit easier to get the locker boards up. Having experienced…